Service Bulletin October 2022

- Kick Off for SEPOS - 3D

- Spühl Monitoring & Analytics

- We Will Overhaul your Knotting Machines

- Instructions: FPC-105 Torque Wrench Changing of Battery and Re-taring

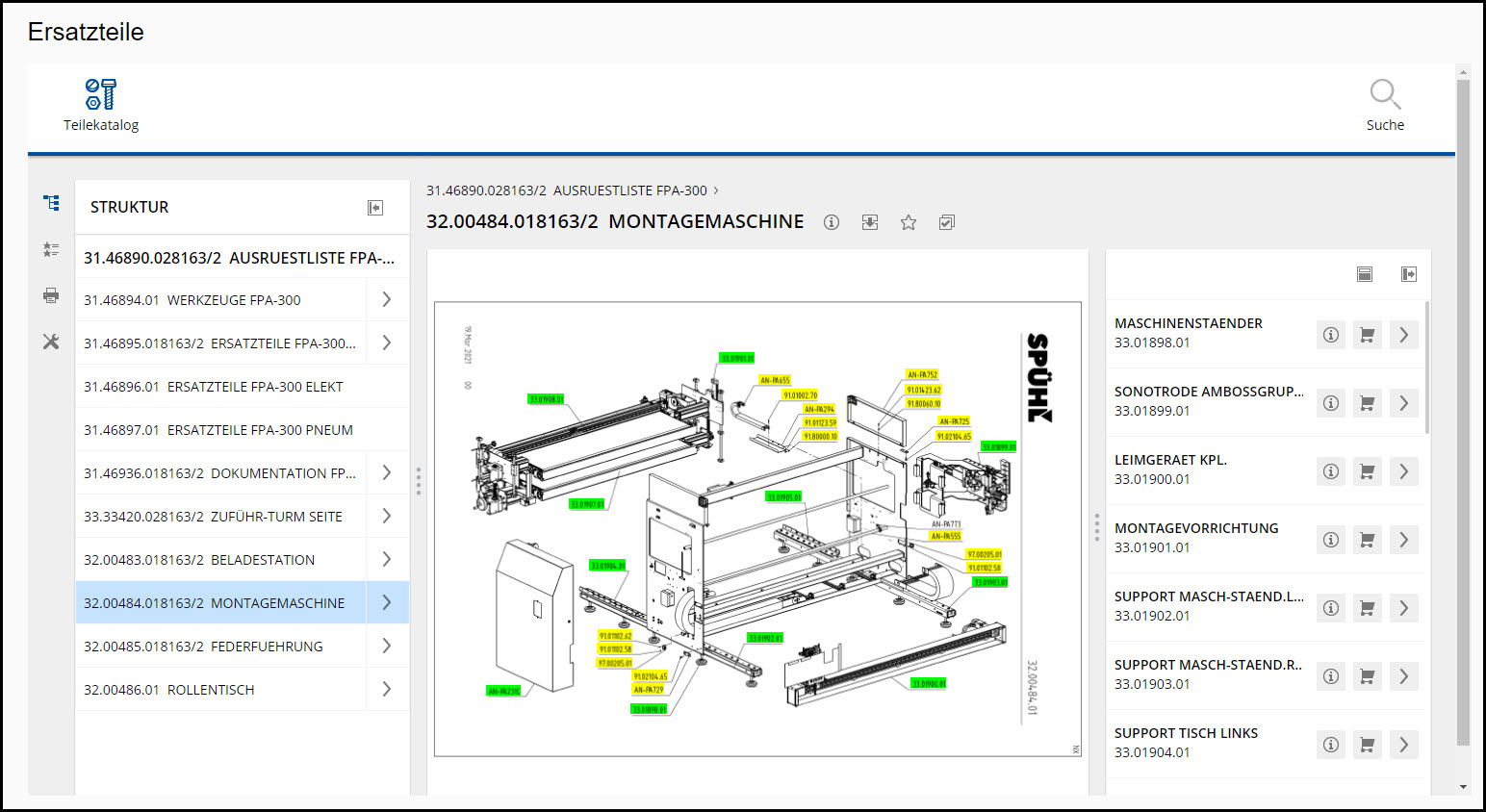

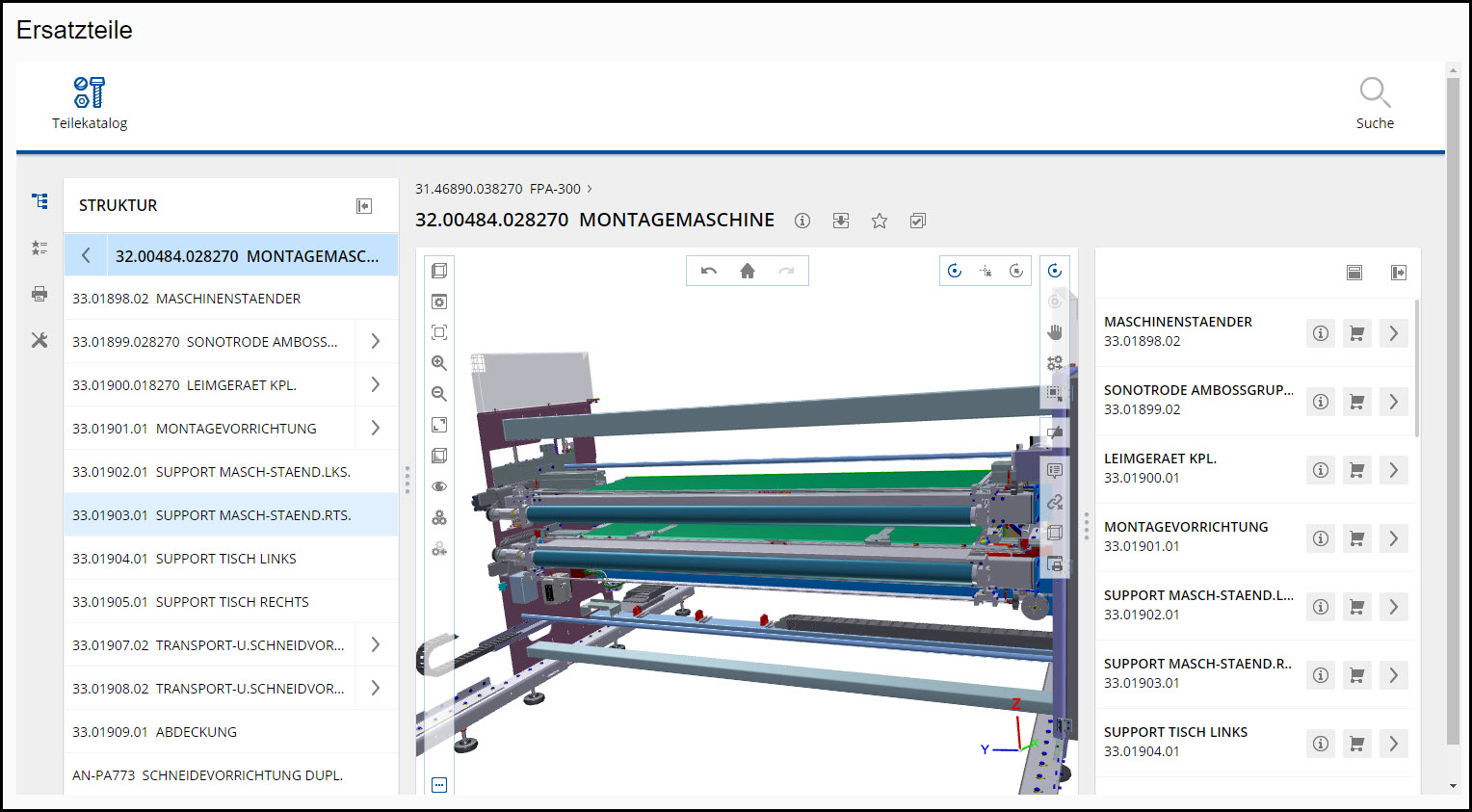

As of now, all new machines will be equipped with SEPOS - 3D. - The first machines with the new 3D spare parts catalog were delivered successfully this month. All of the machines that leave our warehouse from now on will be equipped with this new feature. No integration will take place for older machines that are already in operation, which will remain in the 2D environment. Customers who own new and old machines will not need two different programs. The new display program in SEPOS is able to display both versions. The new functions are only available for the 3D catalog, however.

What’s New?

You can disassemble the components down to the smallest part and rotate them at your convenience. This makes it easier to search for spare parts and promotes understanding of the machine.

Research Every Single Detail

Even the smallest detail is visible and accessible

Quicker Ordering

Replacment parts for orders can be sent more simply and quickly

Valuable Installation Assistance

The 3D function makes the installation process clearly visible

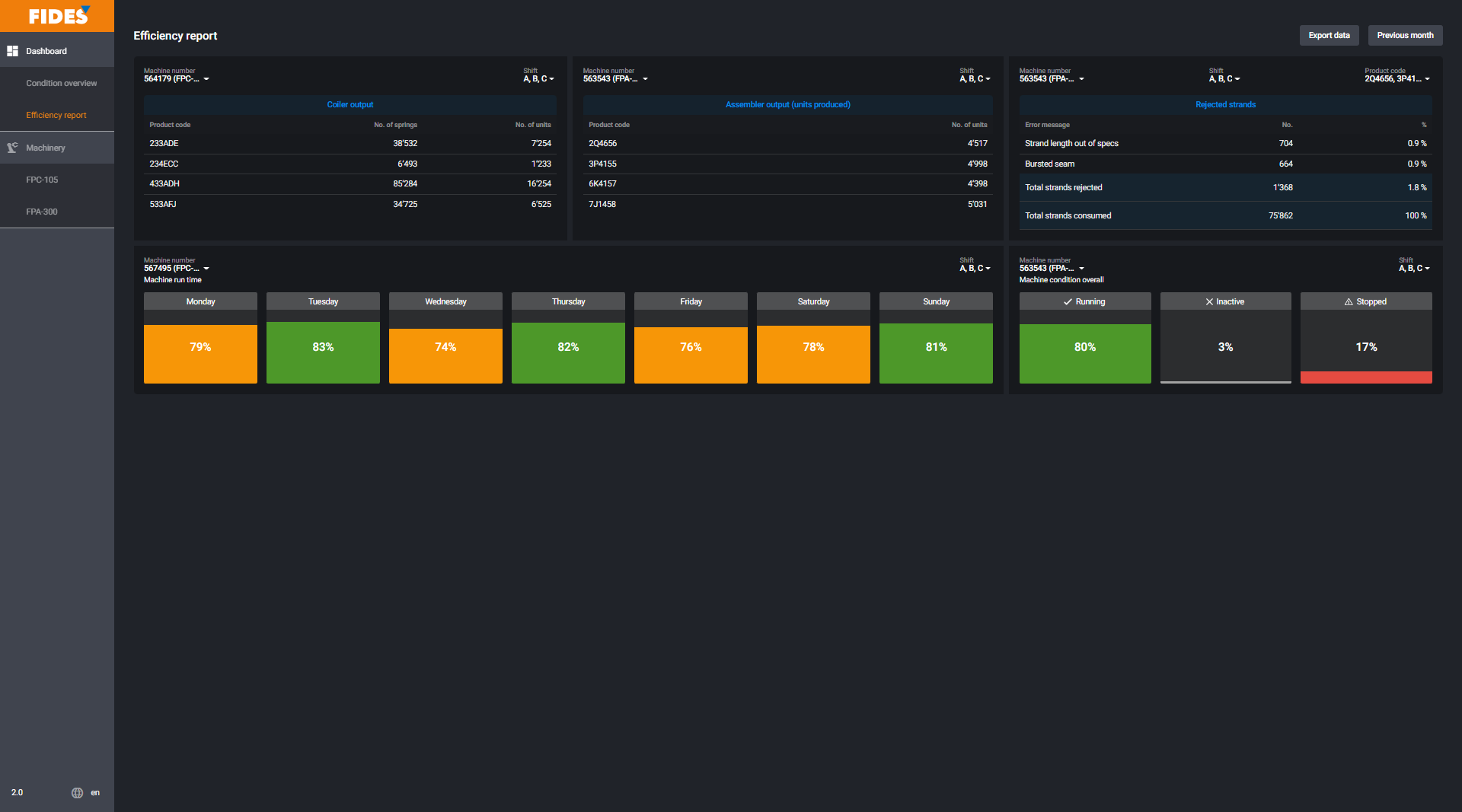

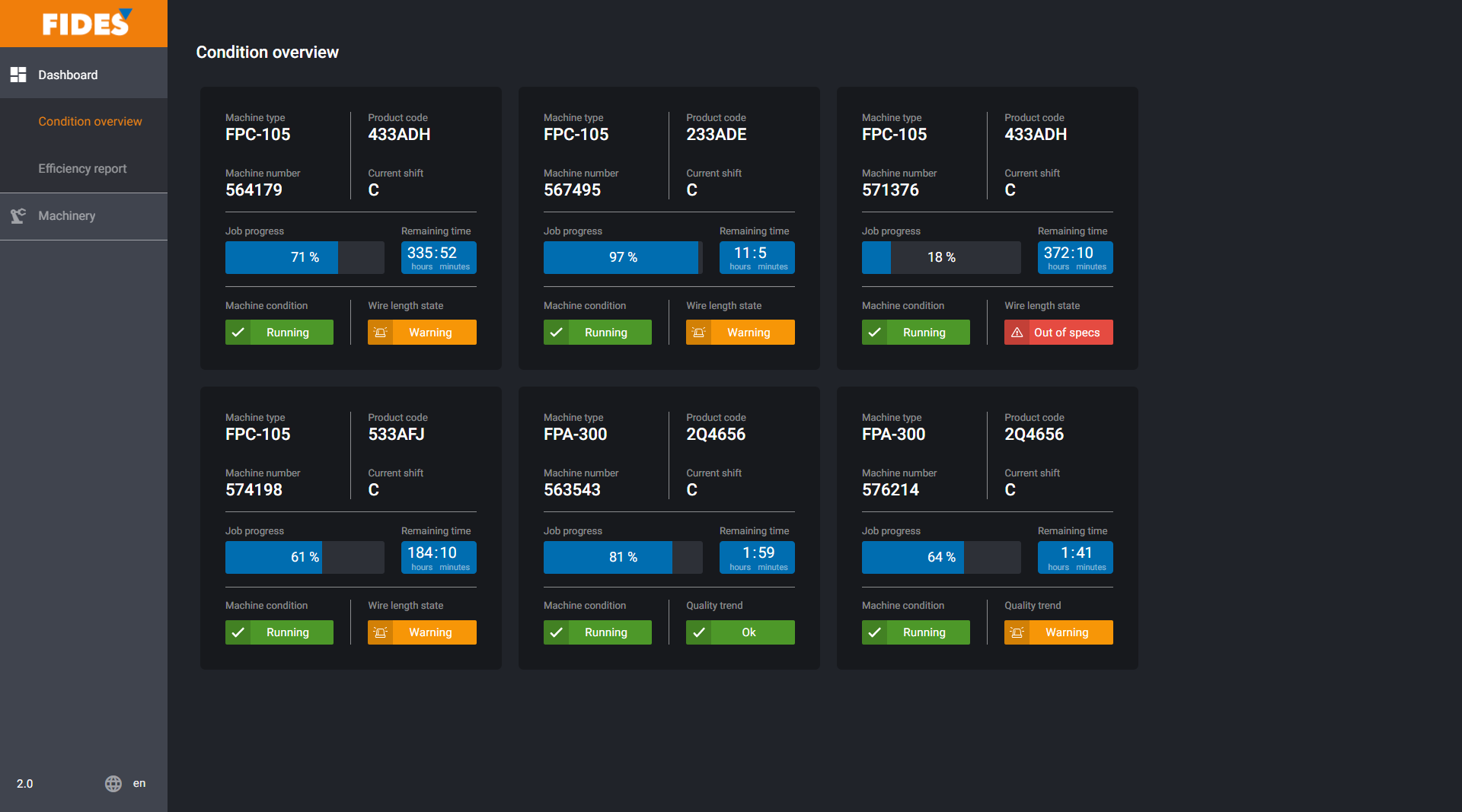

With the new "Spühl Monitoring & Analytics" smart service, we offer our customers a sophisticated platform for optimizing production. Experience shows that the new Smart Service can save you around USD 4,000 per year per coiler machine. But how does it work?

Spühl Monitoring & Analytics uses reports and dashboards to make an important contribution to the transparency of product and process quality. On the one hand you will receive an overview of the current status of the Spühl and Fides machines and on the other hand you receive detailed reports on performance.

In the production of springs and spring core units, Spühl Monitoring & Analytics aims to optimize machine performance. The service offers added value, especially in the areas of raw material consumption and scrap reduction. This means you need less wire and can achieve the aforementioned savings per machine.

In addition, the service allows the quick and simple integration of relevant production data into our customers' production reporting. This is performed by means of a data export in .csv format.

This service is currently available for the FPC-105 and FPA-300machines, additional machines are connected to the solution in an ongoing manner.

If you are interested or would like to obtain more information, please contact us any time via services(at)spuhl.com

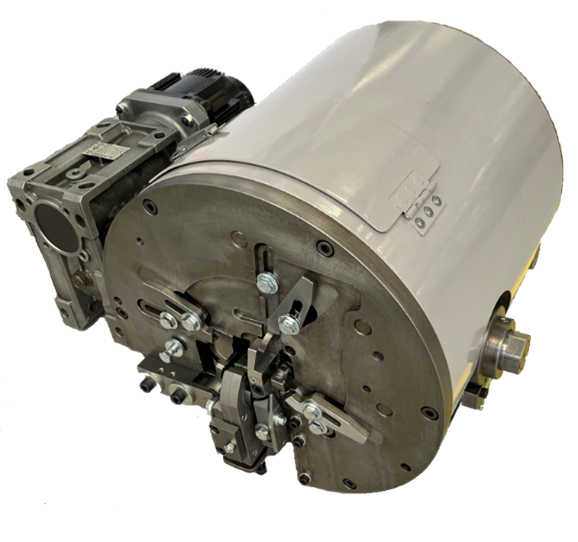

The condition of the knotting machine is crucial to the performance of your spring coiling machines. Ensuring that the knotting machine is well maintained will provide the best and most consistent spring quality.

If you frequently experience problems with your Bonnell machines, which have usually performed well in production, the knotting machine may look like this:

In this case, you can send your knotting machine to Spühl for a complete mechanical overhaul. This is offered at a very attractive price. Spühl charges just EUR 5,500 (excl. shipping) for FT-81, MDC-80, or MDC-72 machine.

Contact us anytime via services(at)spuhl.com and we will be happy to put together an offer for you. This will ensure that your knotting machine both looks and performs like new again.

This article will explain how to replace the batteries in your FPC-105 torque wrench 87.45052.40 and how to re-tare it.

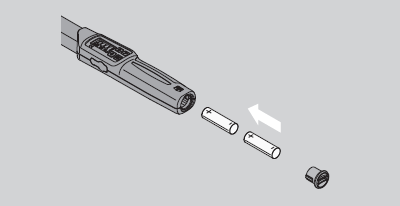

1. Insert Charged Battery Packs/Batteries

To open the battery compartment cover, you will need a suitable object such as a coin.

- Use the coin to turn the cover counterclockwise until it stops.

- Remove the cover.

- Insert the battery pack or batteries observing the polarity specified on the handle.

- Insert the cover into the slot on the battery compartment.

- Press the lid lightly with the coin.

- Use the coin to turn the cover clockwise until comes to a stop.

2. Tare the Torque Wrench

Note: In order to ensure an accurate measurement, the torque wrench must be used for each screwing operation.

Automatic Taring

- Switch on the torque wrench and place it on a flat surface.

- To tare the torque wrench with the plug-in tool installed, allow it to protrude, for example over the edge of the table.

- Ensure that there are no forces acting on the torque wrench.

- Keep the torque wrench still throughout the taring process.

- Press any button to switch on the torque wrench.

- The version number of the software is shown on the display.

- Press the OK button briefly.

- If the Save Values function is switched on, the four-digit bolting case number is displayed.

- To confirm the tightening case, press the OK button. The currently set torque value is displayed.

- The symbol "TARA!" flashes in the display. The torque spanner will be tared within a few seconds.

- If the display shows a value of more than 0.1, then tare the torque spanner manually.

Manual Taring

- Switch on the torque wrench and place it on a flat surface.

- To tare the torque wrench with the plug-in tool installed, allow it to protrude, for example over the edge of the table.

- Ensure that there are no forces acting on the torque wrench.

- Keep the torque wrench still throughout the taring process.

- Press the OK button for longer than 2 seconds.

- The taring process begins. You will see four horizontal lines in the display. The "TARA!" symbol will flash.

- If the display shows a value of more than 0.1 at this time, tare the torque wrench again.